Merkmale

・A bonding material designed using our exclusive silver nanoparticles.

FlowMetal™ nano silver paste is manufactured using silver nanoparticles synthesized by our company.

Specifications with higher silver particle concentration (85-97wt%) are available.

The product is lead-free.

・Low bonding temperature with excellent heat resistance, electrical conductivity, thermal conductivity.

Production technology of low-temperature sintering type silver nanoparticle enables sinter bonding of the nano silver paste at low temperatures.

It is known that silver nanoparticles sinter at low temperature due to the size effect, and the melting point of the sintered silver is similar to that of bulk silver (962℃).

・Pressure-less sintering

In spite of being pressure-less, the low-temperature sintering process provides high bonding strength through diffusion reactions between the nanoparticles and the substrate metal.

Pressure-free sintering may not be suitable depending on the conditions. There is also specifications for sintering with pressure.

Druckverfahren

Dispenser, metal mask (stencil) printing, or pin transfer process are available.

Applicable Surfaces

Gold, Silber, Kupfer

Product Specifications

Die Werte in der Tabelle sind repräsentative Werte. Die Spezifikationen können ohne Vorankündigung geändert werden.

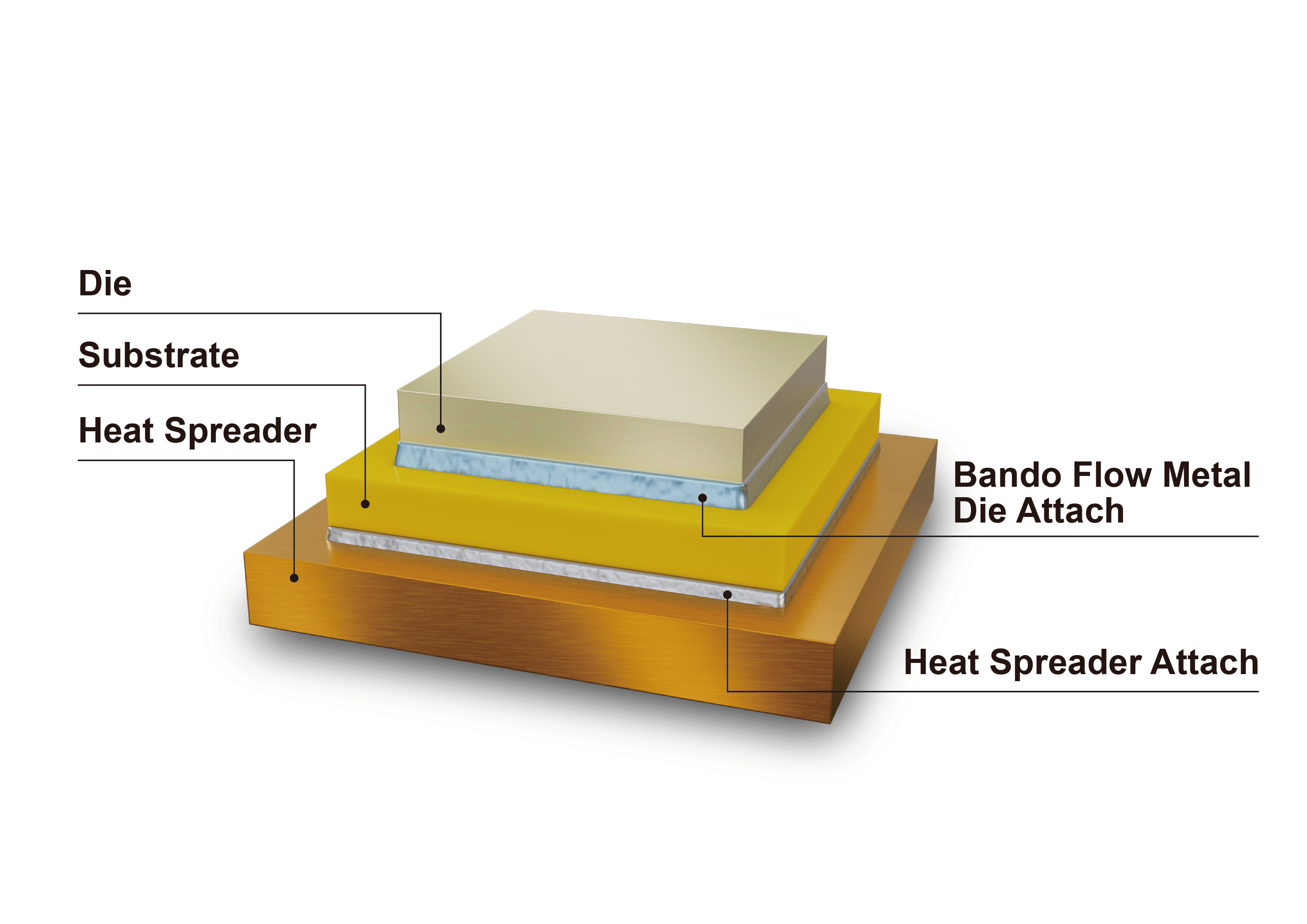

Anwendungen

Beispiel für den Druck auf einem Halbleiterchip

Anwendungen & Fallbeispiele

Wir stellen unsere Produktanwendungen und Fälle für verschiedene Branchen vor.