Características

・Un material de unión diseñado utilizando nuestras exclusivas nanopartículas de plata.

La pasta de nanoplata FlowMetal™ se fabrica utilizando nanopartículas de plata sintetizadas por nuestra empresa.

Hay disponibles especificaciones con mayor concentración de partículas de plata (85-97 % en peso).

El producto no contiene plomo.

・Baja temperatura de unión con excelente resistencia al calor, conductividad eléctrica y conductividad térmica.

La tecnología de producción de nanopartículas de plata de tipo sinterizado a baja temperatura permite la unión por sinterización de la pasta de nanoplata a bajas temperaturas.

Se sabe que las nanopartículas de plata se sinterizan a baja temperatura debido al efecto del tamaño, y el punto de fusión de la plata sinterizada es similar al de la plata a granel (962 ℃).

・Sinterización sin presión

A pesar de no tener presión, el proceso de sinterización a baja temperatura proporciona una alta fuerza de unión a través de reacciones de difusión entre las nanopartículas y el metal del sustrato.

La sinterización sin presión puede no ser adecuada según las condiciones. También existen especificaciones para la sinterización con presión.

Método de impresión

Se encuentran disponibles procesos de impresión con dispensador, máscara de metal (plantilla) o transferencia de pines.

Superficies aplicables

Oro, plata, cobre

Especificaciones del producto

Los valores de la tabla son valores representativos. Las especificaciones están sujetas a cambios sin previo aviso.

Aplicaciones

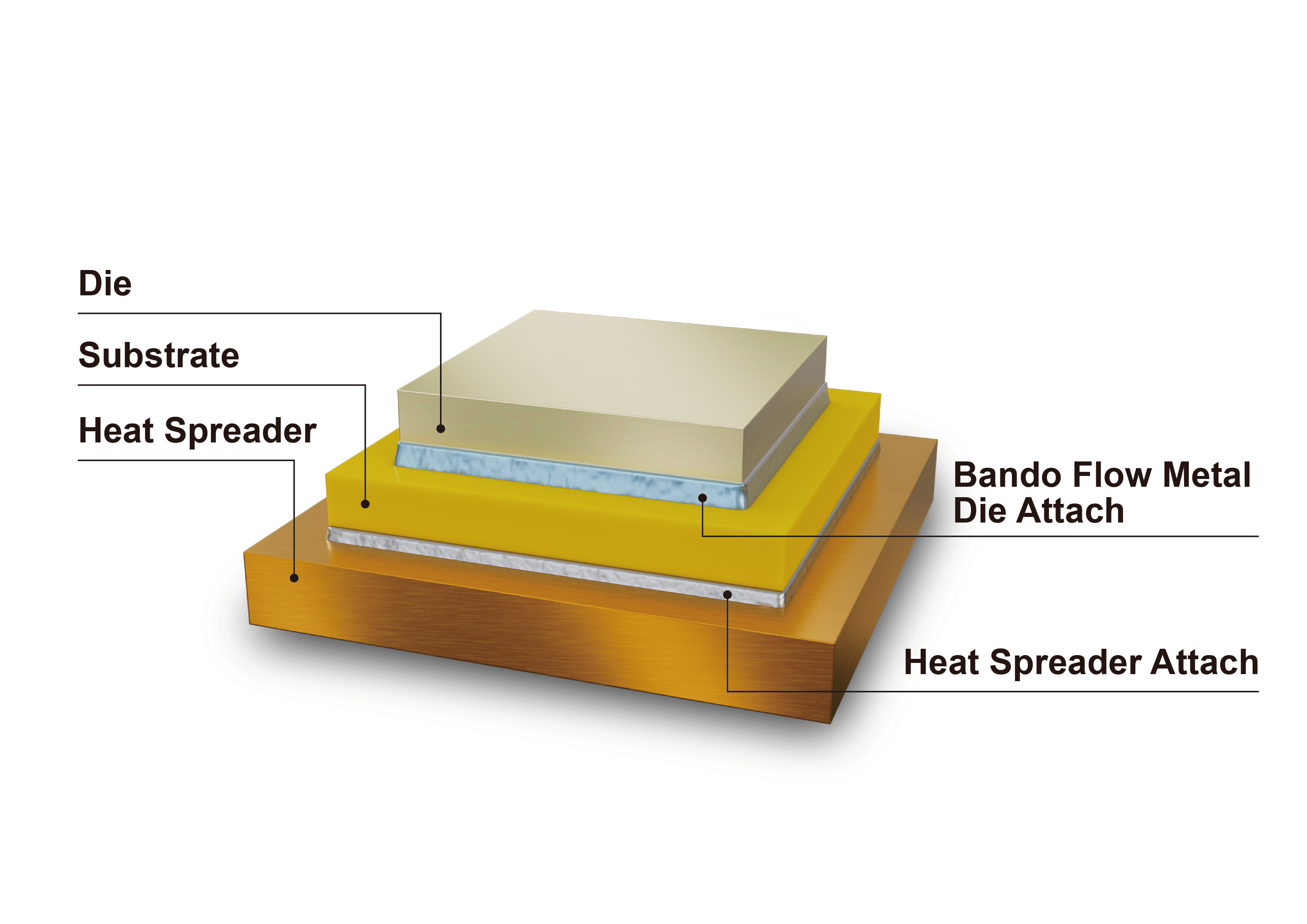

Ejemplo de impresión en una matriz semiconductora

Aplicaciones y casos

Presentamos las aplicaciones y casos de nuestros productos para diversas industrias.