Comment la CVT rend les véhicules électriques plus efficaces

La CVT est un type de transmission capable de convertir la puissance de rotation du moteur en continu. Sa principale caractéristique est sa transmission continue, contrairement aux vitesses d'un vélo.

La CVT permet de modifier en continu le rapport de vitesse variable, ce qui permet de maintenir le régime moteur à un niveau optimal. Cela présente de nombreux avantages, notamment un meilleur rendement du véhicule électrique, des performances d'accélération, une meilleure maniabilité en côte et une meilleure capacité de charge.

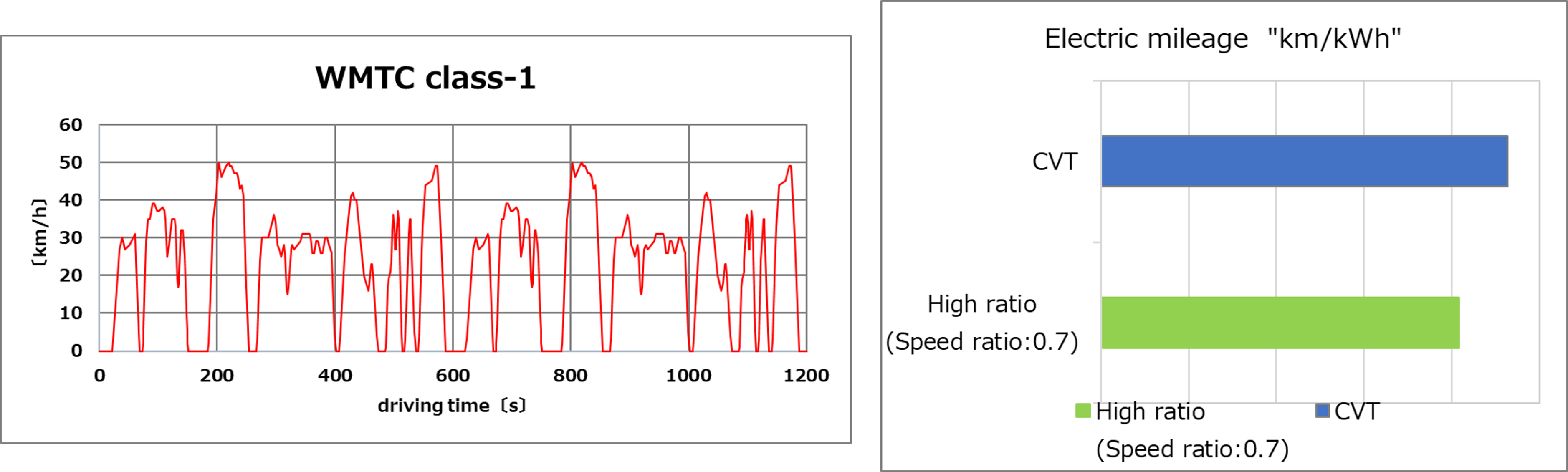

Consommation électrique améliorée de 5 %

Nous avons comparé la force motrice de vélos électriques CVT disponibles sur le marché : l'un conservait la transmission CVT et l'autre adoptait une transmission à rapport fixe. Pour obtenir des données comparatives détaillées, veuillez cliquer sur le lien ci-dessous pour télécharger le document.

Outre la force motrice, nous avons également mesuré la consommation électrique. Les résultats ont montré une amélioration d'environ 5 % de la consommation électrique avec l'installation de la CVT. Cette mesure a été réalisée en mode WMTC.

Mode WMTC : un mode de conduite (commande de vitesse du véhicule) permettant d'évaluer la consommation de carburant ou la consommation électrique. Le mode WMTC est une norme mondiale développée par le Forum mondial des Nations Unies pour l'harmonisation des normes relatives aux véhicules.

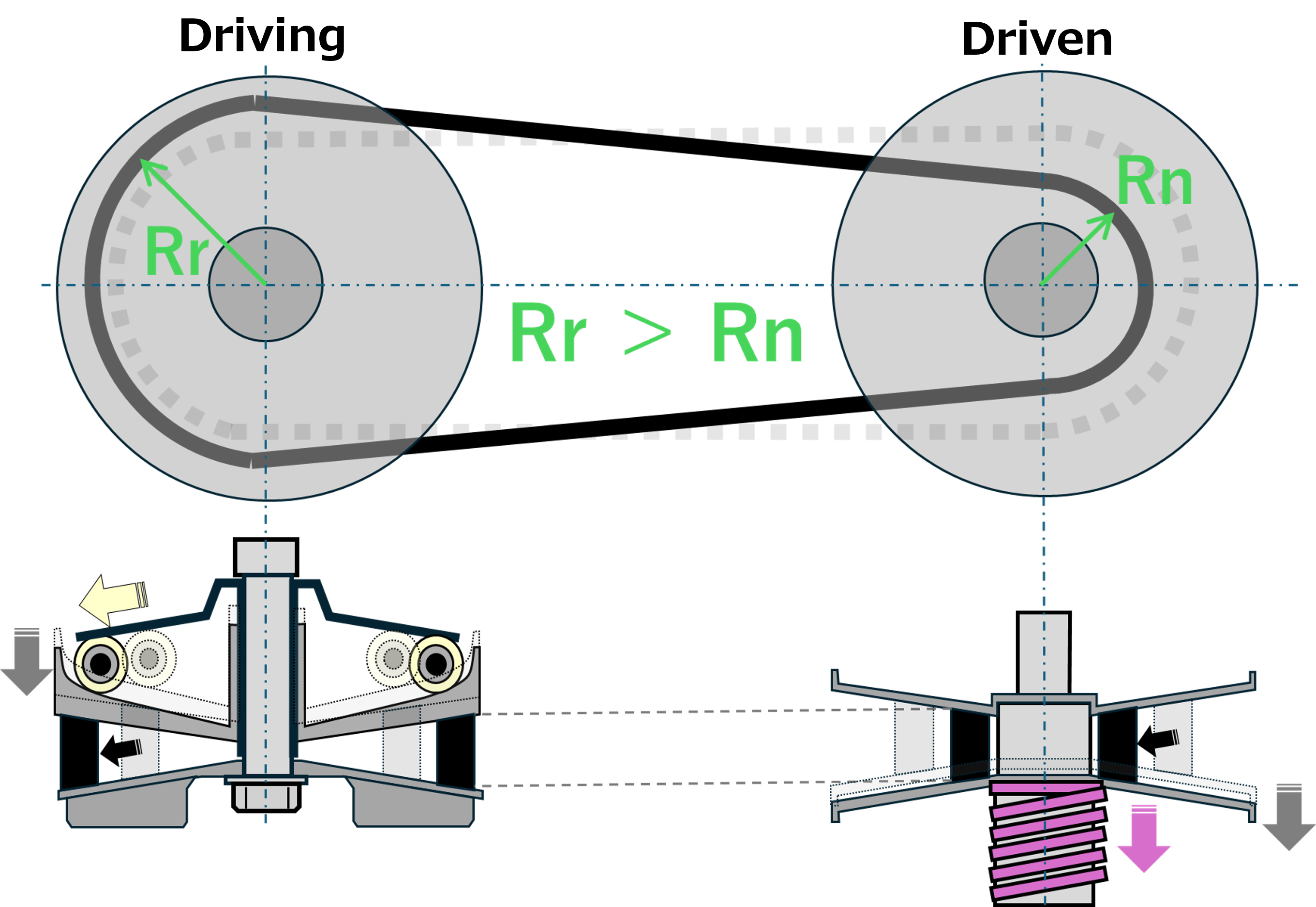

Structure de la CVT

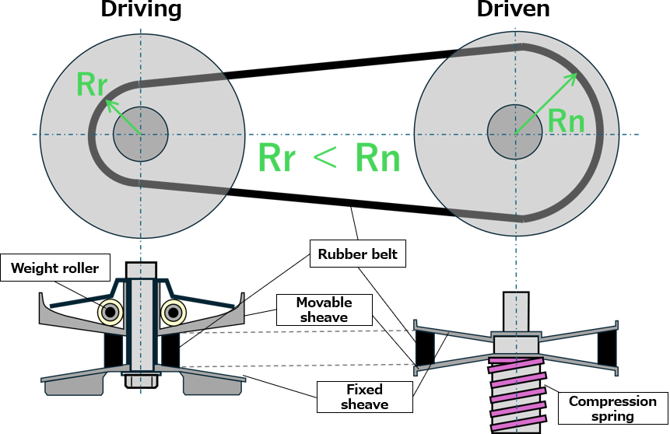

La transmission à variation continue (CVT) est composée d'une poulie avec un rouleau, appelé « rouleau de masse », et d'une courroie de transmission. Voici une explication du fonctionnement du changement de vitesse en continu.

Figure 1 : la moitié supérieure est une vue de côté, et la moitié inférieure présente les coupes transversales des côtés moteur et entraînement. Le côté moteur est constitué de galets de masselotte, d'une poulie mobile et d'une poulie fixe, tandis que le côté entraînement est constitué d'une poulie mobile, d'une poulie fixe et d'un ressort de compression. La figure 1 illustre une faible vitesse, où le diamètre de la courroie enroulée autour du côté entraînement est supérieur à celui du côté entraînement. À ce moment, les galets de masselotte sont situés du côté de l'axe central. Par conséquent, le régime diminue et le couple augmente du côté entraînement par rapport au côté entraînement.

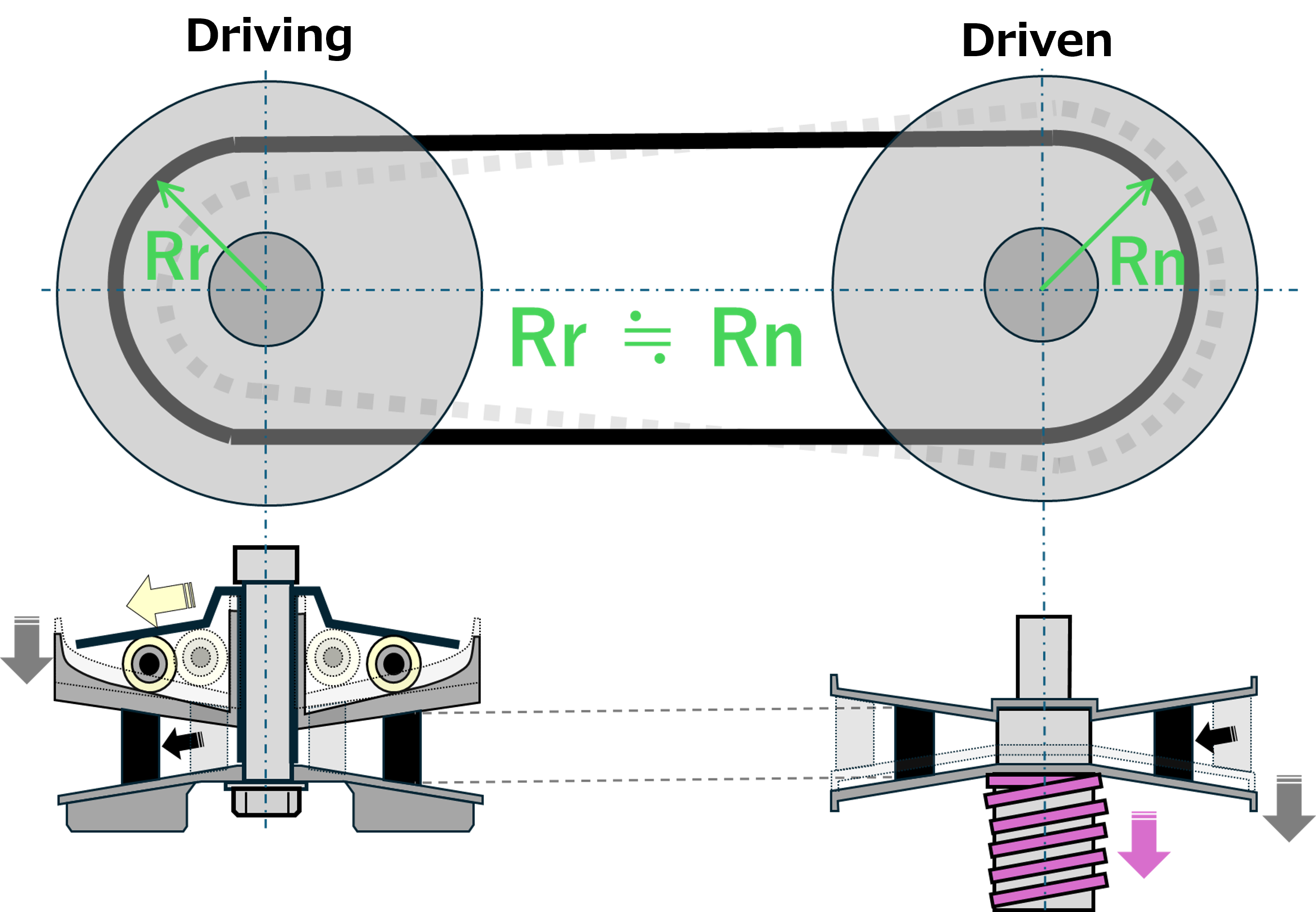

La figure 2 illustre un régime moyen. À mesure que le régime augmente, la force centrifuge des galets de masse du côté moteur l'emporte sur la force du ressort de compression du côté entraîné, provoquant un déplacement radial des galets vers l'extérieur. Ceci provoque le déplacement de la poulie mobile du côté moteur vers le bas, augmentant ainsi le diamètre de la courroie enroulée autour du côté moteur. Le diamètre d'enroulement du côté entraîné diminue d'autant. Comparé à un régime faible, le régime augmente et le couple diminue du côté entraîné.

La figure 3 illustre une vitesse élevée. À haut régime, la force centrifuge des rouleaux de masse augmente davantage qu'à vitesse moyenne, ce qui augmente encore le diamètre de la courroie côté entraînement. Par conséquent, le régime côté entraînement augmente et le couple diminue par rapport à la vitesse moyenne.

De cette façon, la CVT permet un changement de vitesse en douceur en faisant varier le diamètre d'enroulement de la courroie avec les rouleaux de poids.

Les CVT se divisent en deux types : les CVT à courroie, utilisées sur les motos et les voitures particulières, et les CVT toroïdales, utilisées sur les grosses voitures particulières. Les CVT à courroie se divisent elles-mêmes en deux types : les courroies métalliques et les courroies en caoutchouc, les courroies en caoutchouc étant utilisées sur les motos et les tricycles, et les courroies métalliques sur les voitures particulières.

Courroie en caoutchouc BANDO pour CVT

Vaste expérience dans les courroies pour CVT utilisées dans les moteurs à combustion interne

Il existe deux types de courroies en caoutchouc : les courroies de friction, qui sont également utilisées pour les courroies de ventilateur dans les automobiles, et les courroies synchrones, qui sont utilisées pour les composants OHC et de précision dans les automobiles.

Courroies de friction ・・・ Courroies de ventilateur automobile, etc.

Courroie synchrone ・・・ OHC, machines de précision, etc.

Les courroies en caoutchouc sont utilisées dans les transmissions à variation continue (CVT) à courroie pour motos et tricycles. Nos courroies de friction sont largement utilisées dans les CVT des motos équipées de moteurs à combustion interne.

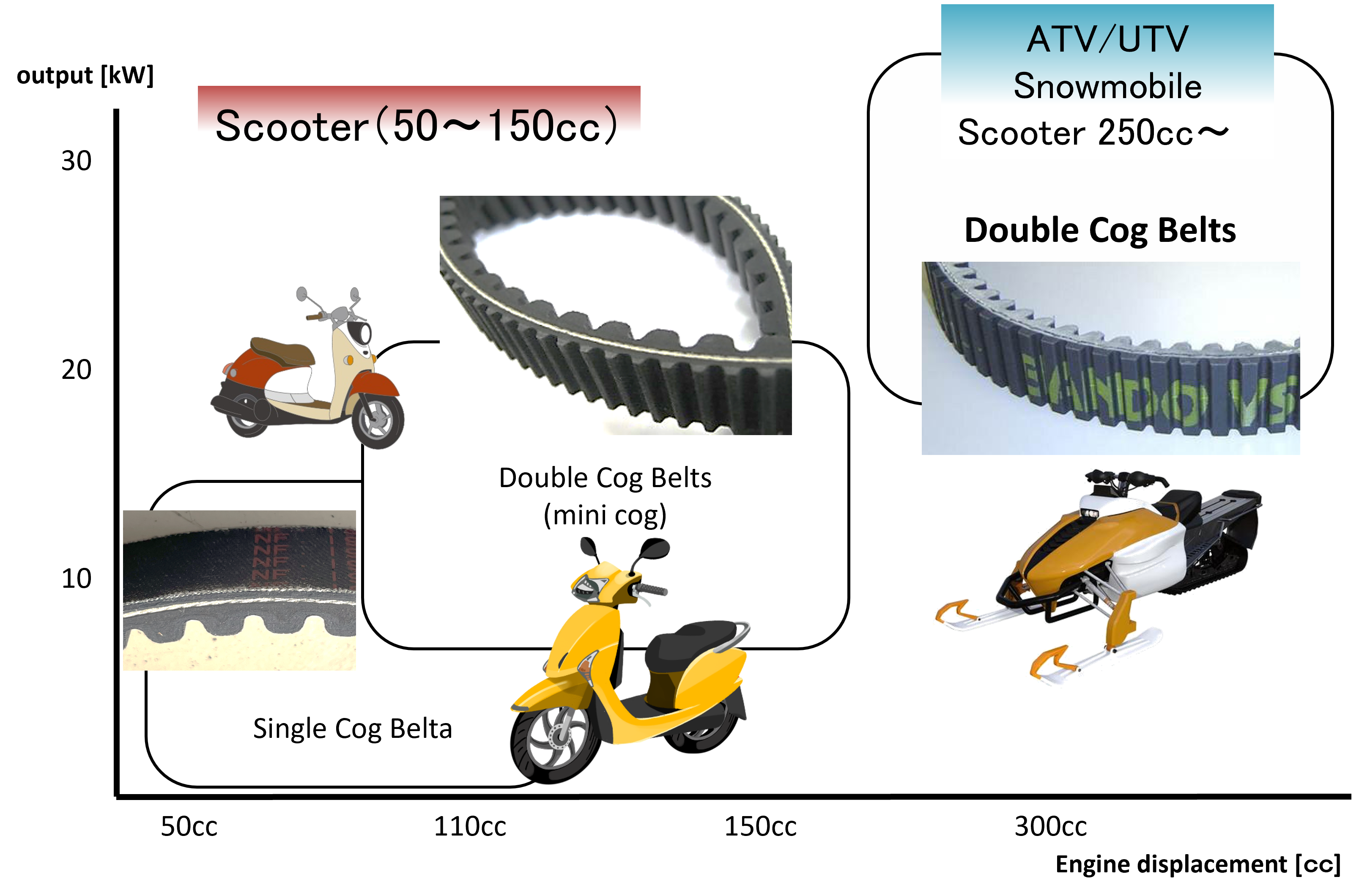

Les courroies de friction utilisées dans les CVT sont à simple, double et mini-double pignon. Les courroies utilisées diffèrent selon la puissance (cylindrée) ; des exemples d'utilisation sont présentés ci-dessous.

Pignon simple ・・・ Scooters de 50 à 150 cc

Double pignon ・・・ VTT/UTV, motoneige et gros scooter de plus de 250 cc

Mini Double COG ・・・ Scooters 125cc

Avec une telle expérience dans les courroies CVT pour moteurs à combustion interne, nous sommes également en mesure d'optimiser la conception des courroies pour CVT pour véhicules électriques.

Première mondiale ! Courroies hautes charges en caoutchouc composite à base de nanofibres de cellulose

Nous avons développé et commercialisé la première courroie crantée double au monde en caoutchouc composite à base de nanofibres de cellulose (CNF). Cette courroie, fabriquée à partir de ce caoutchouc composite, répond aux exigences d'élasticité élevées des courroies de friction CVT de nouvelle génération et offre d'excellentes performances en termes de transmission, de résistance à la séparation, d'abrasion et de fissuration, qui constituent les exigences de performance fondamentales des courroies.

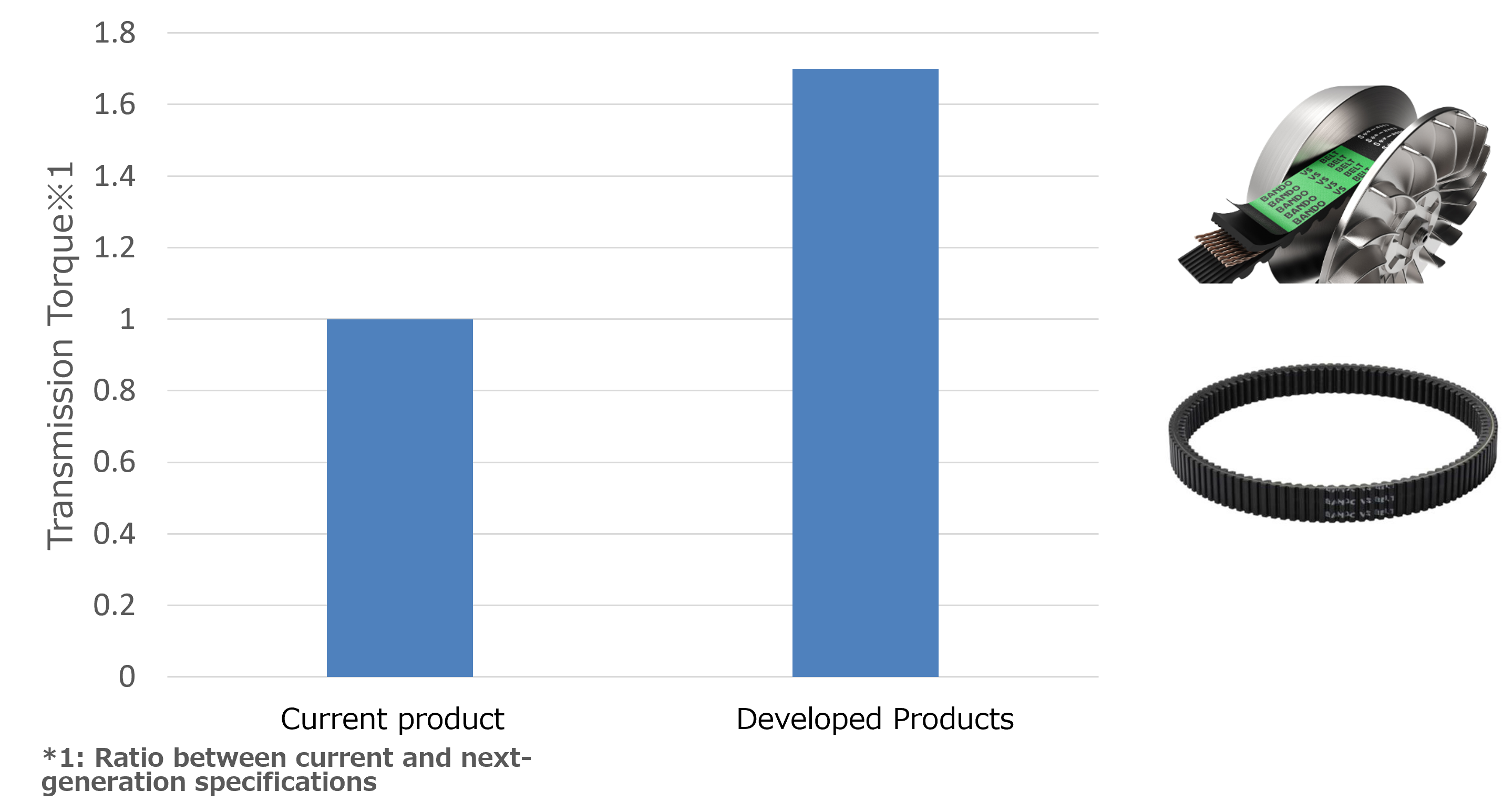

Le graphique ci-dessous compare la bande actuelle et la bande contenant des nanofibres de cellulose. Comparée à la bande actuelle, la bande contenant des nanofibres de cellulose présente une capacité de transmission environ 1,7 fois supérieure à celle de la bande contenant des nanofibres de cellulose.

Plus l'élasticité de la courroie CVT est élevée, plus sa durabilité et sa capacité de transmission sont élevées. Cela présente l'avantage majeur de réduire la taille de la courroie et d'optimiser la compacité de la transmission CVT.