[Video] On-site joint of plastic conveyor belts can be done in two steps.

- #Improved maintainability

- #Increased productivity

- #Manpower saving

- #Cargo handling equipment

- #Light duty conveyance product

At sites that operate 24 hours a day, when a belt suddenly breaks down and needs to be replaced, it may take a long time to arrange for a press machine and installer to perform the joint by heat fusion welding.

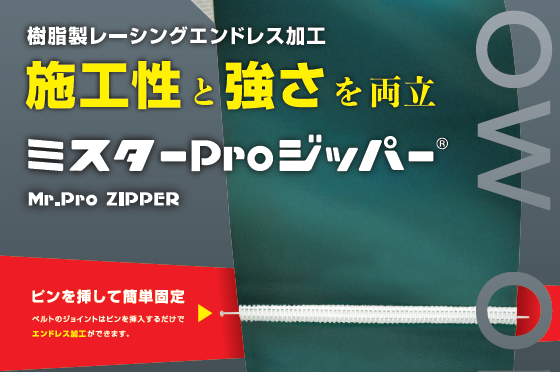

Mr. Pro Zipper™ allows customers to make joints on site in just two steps, without the need for a press or other equipment.

The joint part is made of resin, not metal, so it is gentle to the material being conveyed, making it ideal for conveying linens and other fabrics.

(For product details, please refer to the link at the bottom of this page.)

- #Improved maintainability

- #Increased productivity

- #Manpower saving

- #Cargo handling equipment

- #Light duty conveyance product