Advantages

1. Applicable in higher torque transmission.

Ceptor™-X has 20% higher transmission capacity than Ceptor™-Ⅵ.

2. Produce lesser noise

Ceptor™-X has higher transmission capacity which reduce belt width, thus lesser noise.

3.Fit to use in compact design

With higher transmission capacity, belt width and size of pulley can be reduced.

4.Provide high positioning accuracy and good responsivity

High modulus carbon fiber cords enable higher positioning accuracy and responsivity.

5.Higher durability against tooth chipping

High modulus synthetic rubber to provide better durability against teeth chipping.

6.Usable with standard STS pulleys

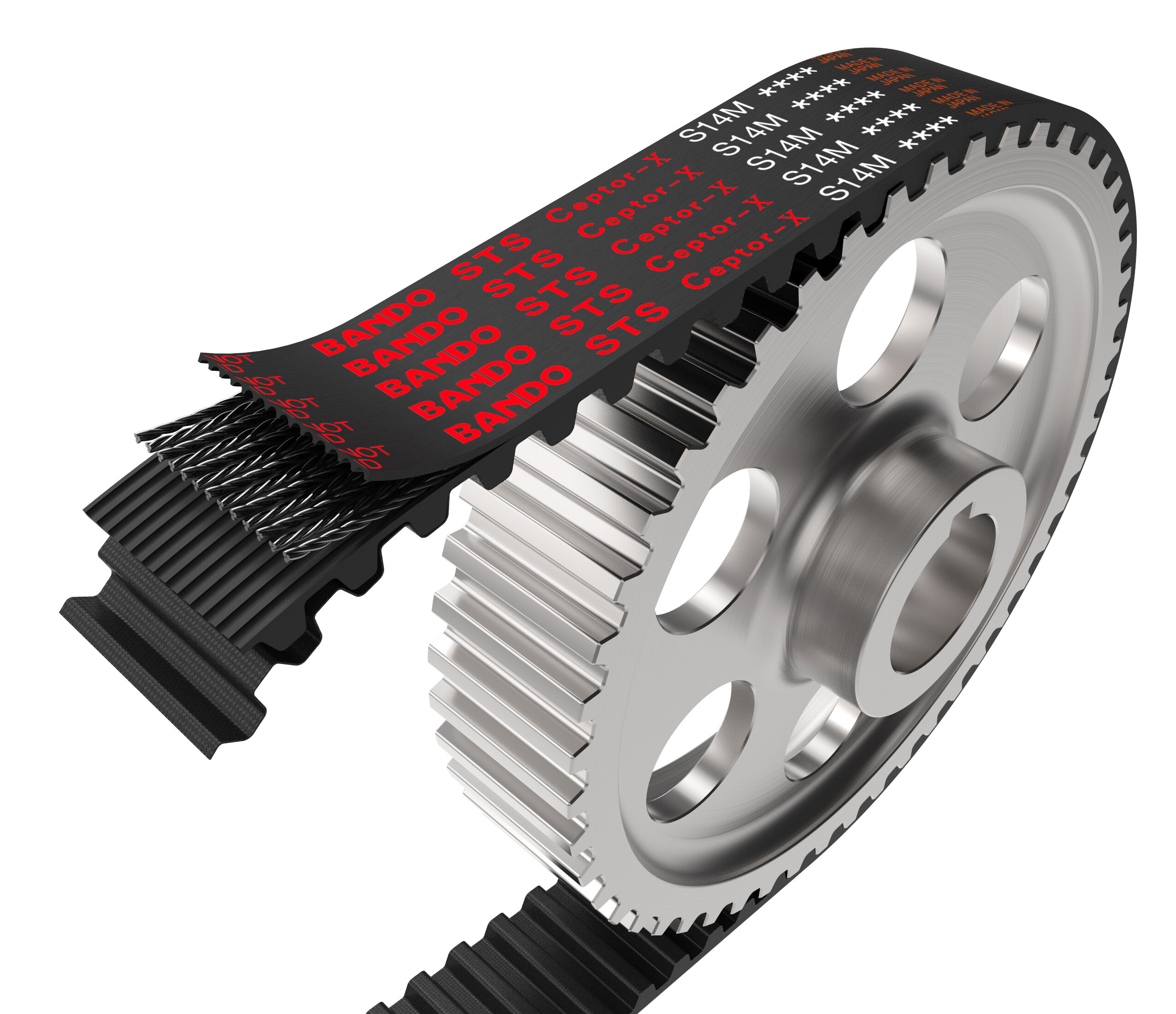

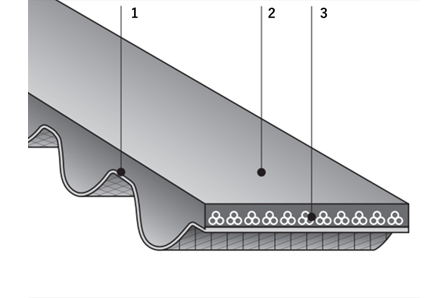

Structure

1. Rubber : High modulus synthetic rubber to minimize tooth deformation.

2. Canvas: Durable canvas with excellent abrasion resistance.

3. Cords: Carbon fiber cords for higher transmission capacity, positioning accuracy and responsivity

**Ceptor™-X S3M has specification for clean environment use.

Enhanced transmission capacity

Compared with Ceptor™-Ⅵ, transmission capacity is increased by 20%

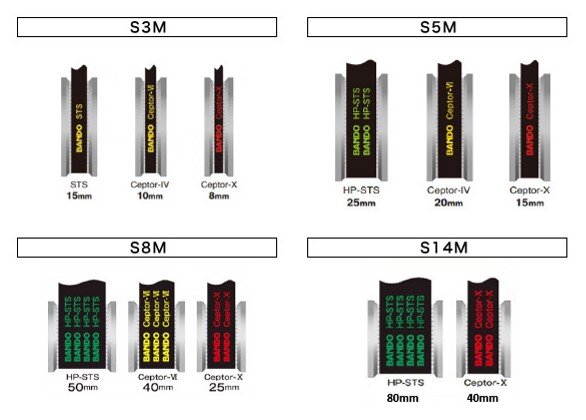

Design Compactification

With the same transmission condition, Ceptor™-X is usable with smaller belt width compared to conventional belts.

Recommended products

Frequently viewed products related this page.

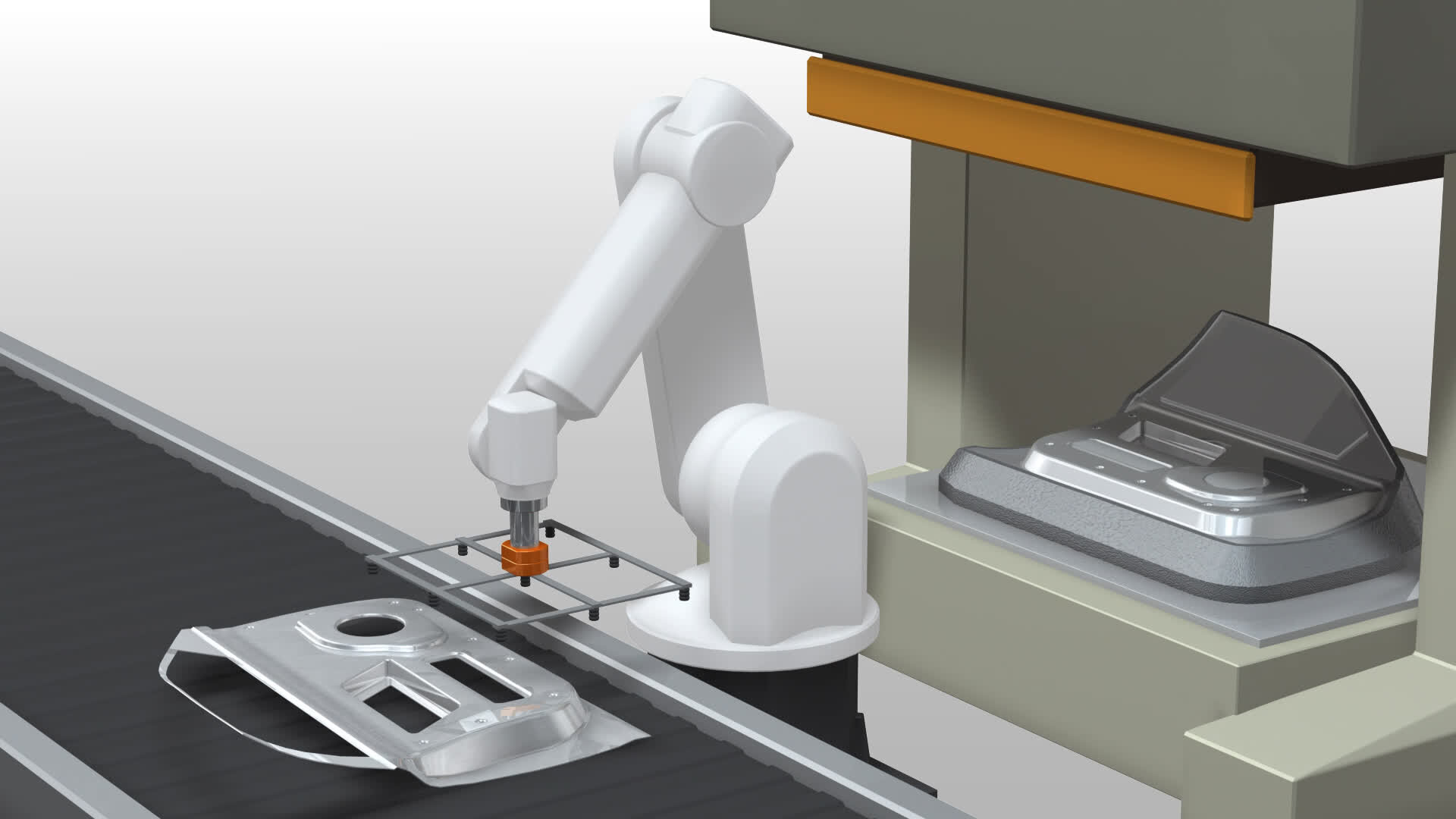

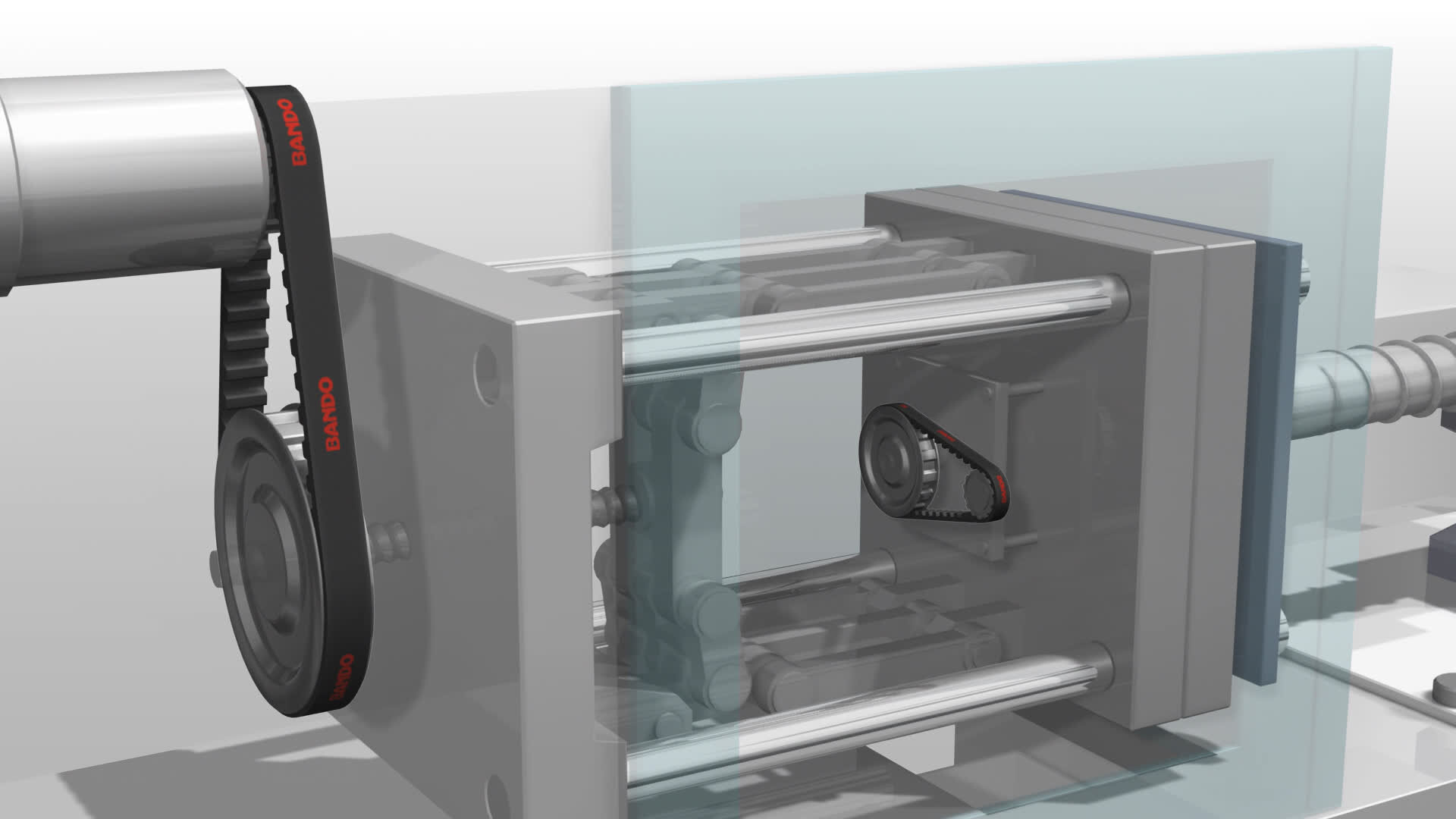

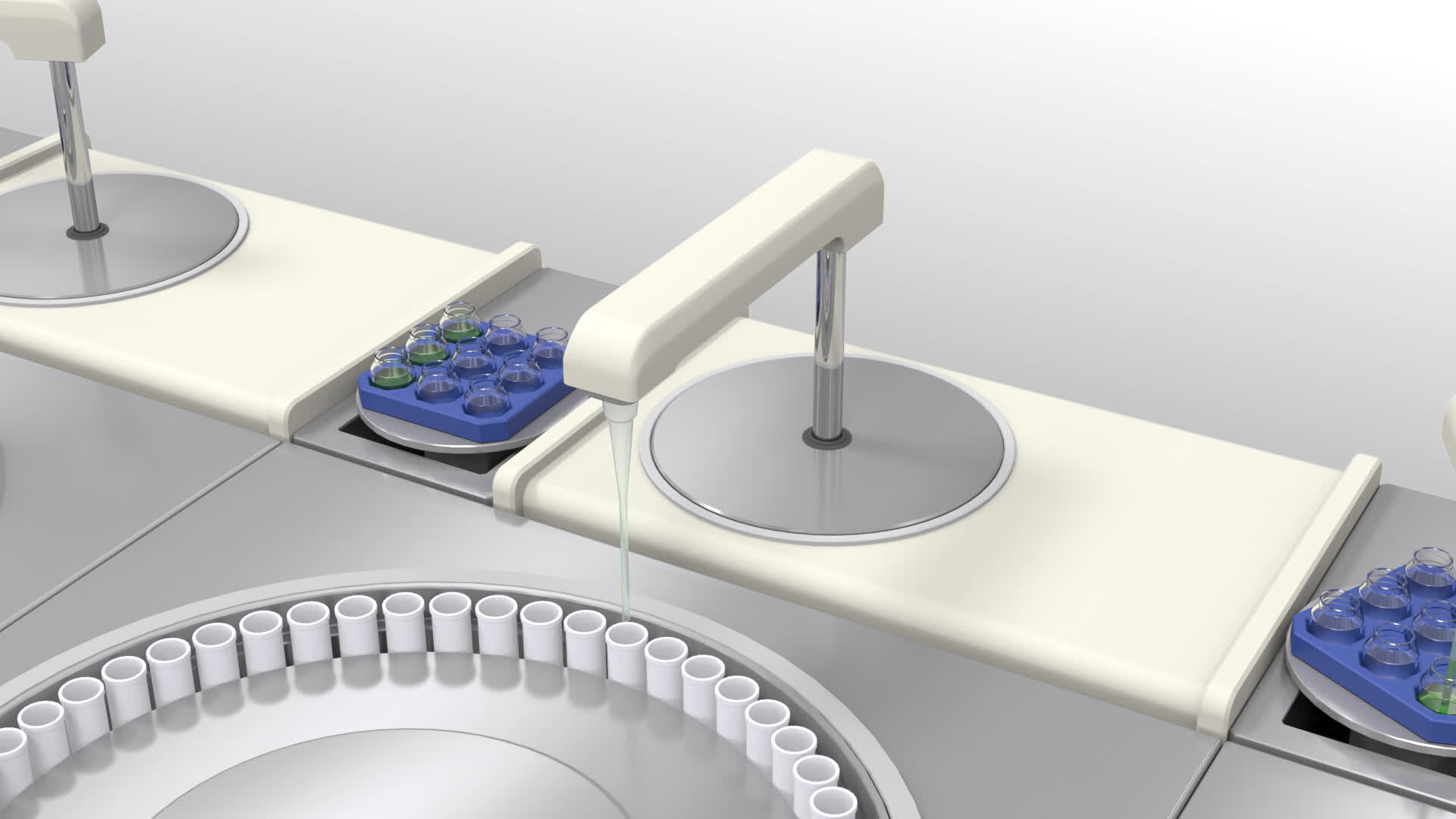

Applications & Cases

Introducing our product applications and cases for various industries.