Advantages

1.Reduce energy consumption by 7% compare to the conventional V-Belt.

2.Minimize re-tensioning work as the auto-tensioner maintains belt tension automatically.

3.Demonstrate 3 times longer service life than conventional V-Belt.

4.Enable compact design with smaller pulley width and diameter.

Applications

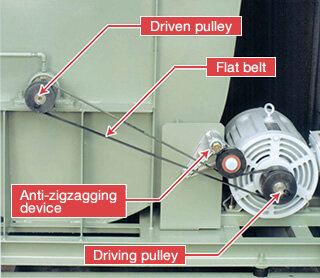

By attaching a special pulley to control the snaking of the flat belt, the running of the belt is adjusted autonomously.

As the belt tension is maintained optimally by auto-tensioner, longer service life is achieved and

maintenance-free installation becomes possible.

For installation, A and B sections are to be fixed onto the brackets (mounting plates) as designed to keep the belt running at optimal tension.

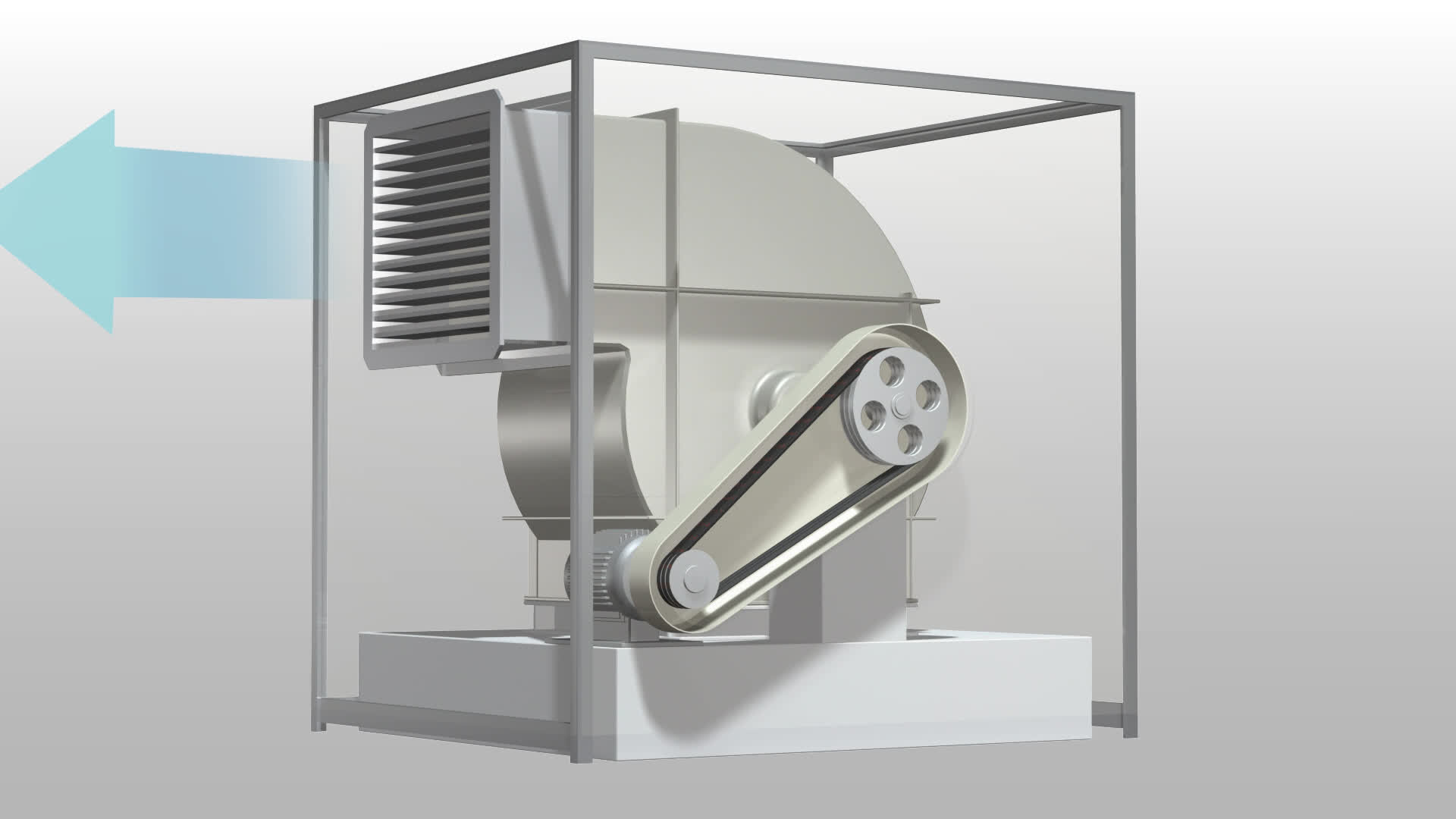

1. Air handling units

2. Industrial blowers

3. Industrial vacuum dust cleaner

4. Industrial compressors, Screw compressors

Applications & Cases

Introducing our product applications and cases for various industries.