Features

The exposed rubber on the side face has a high coefficient of friction and high transmission capacity.

In addition, the reinforcing fibers have been improved to enhance side pressure resistance and can be used for large-mold agricultural machinery.

The cog shape (corrugated bottom face) and specially woven canvas provide excellent flexibility for small pulley diameters and reverse bends.

In addition, bending loss is reduced, internal heat generation is reduced, and service life is improved.

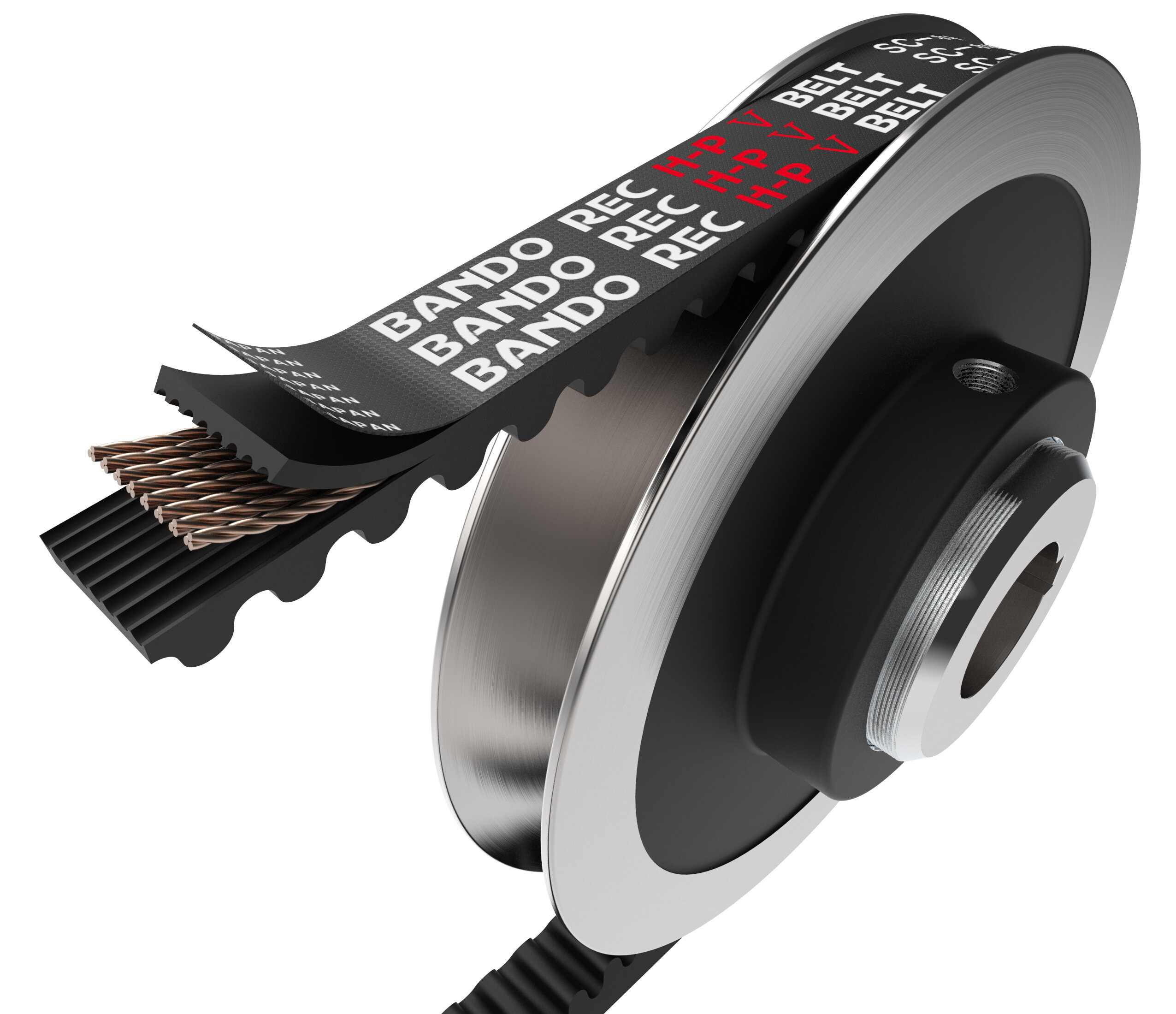

Structural differences between wrapped V Belts and raw edge cog belts

[Wrapped V Belts

Both the side face and bottom face are covered with canvas for excellent abrasion resistance. It allows smooth transmission of power. It also helps protect the machine.

Structure: (1) cover fabric, (2) tension rubber, (3) cord, (4) compression rubber, (5) laminated fabric

[Low edge cog belt].

The side face has exposed rubber for high transmission. The power from the motor is transmitted firmly. Often used around drive units.

Structure: (1) top fabric, (2) tension rubber, (3) cord, (4) compression rubber, (5) bottom fabric

Performance comparison of RED S-II (*) and H-PV

Transmission capacity is about 1.5 times that of RED S-II. 5 times, but with smaller pulley diameter than RED S-II.

(*RED S-II is a type of wrapped V Belts used in agricultural machinery.)

Application

Large-mold agricultural machinery such as tractors, combine harvesters, rice transplanters, etc.

Applications & Cases

Introducing our product applications and cases for various industries.