Features

1. Various specifications of insulation.

2. High thermal conductivity, one of the highest on the market.

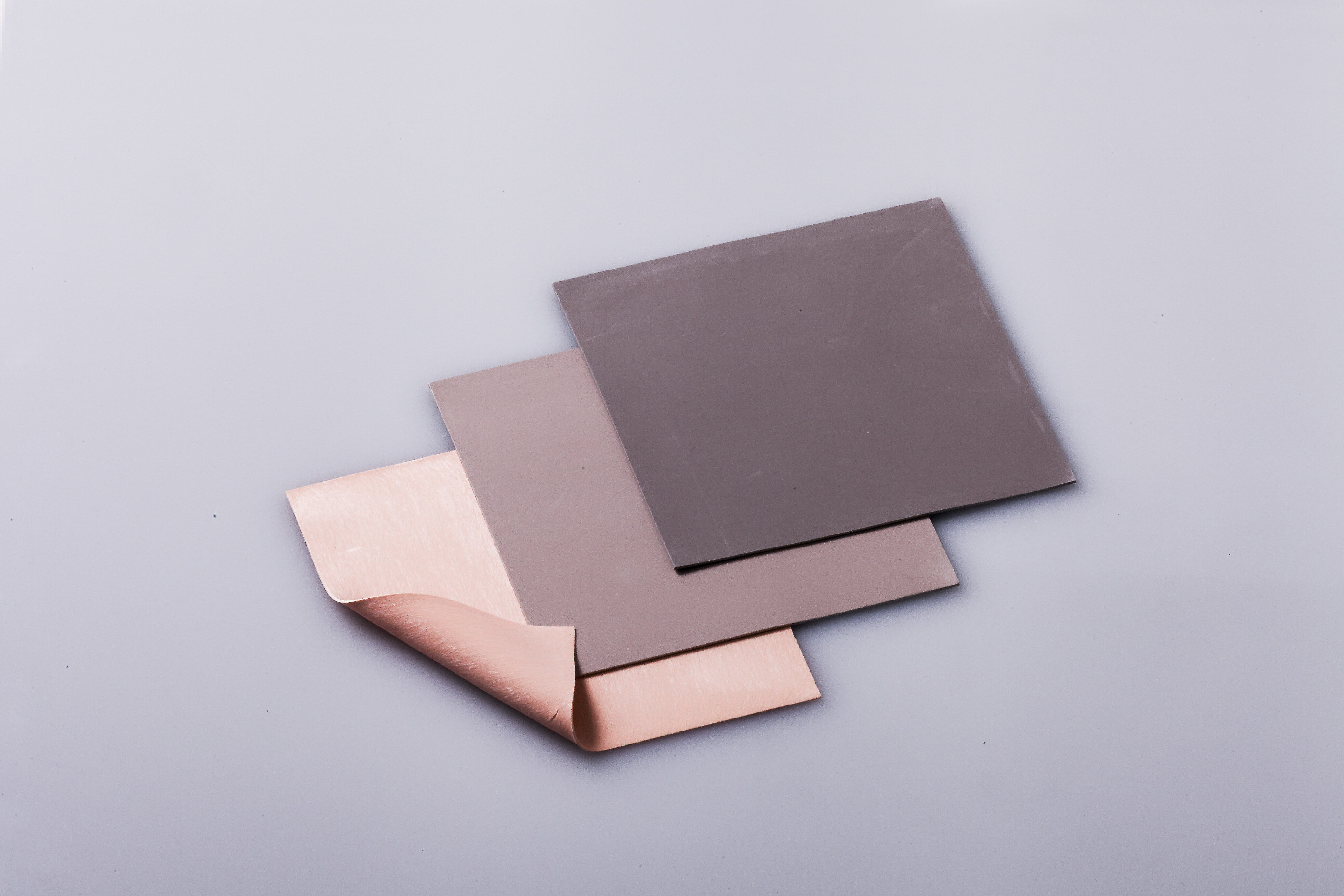

3. A rubber type soft sheet TIM without being over adhesive.*

(*) TIM : Thermal Interface Material

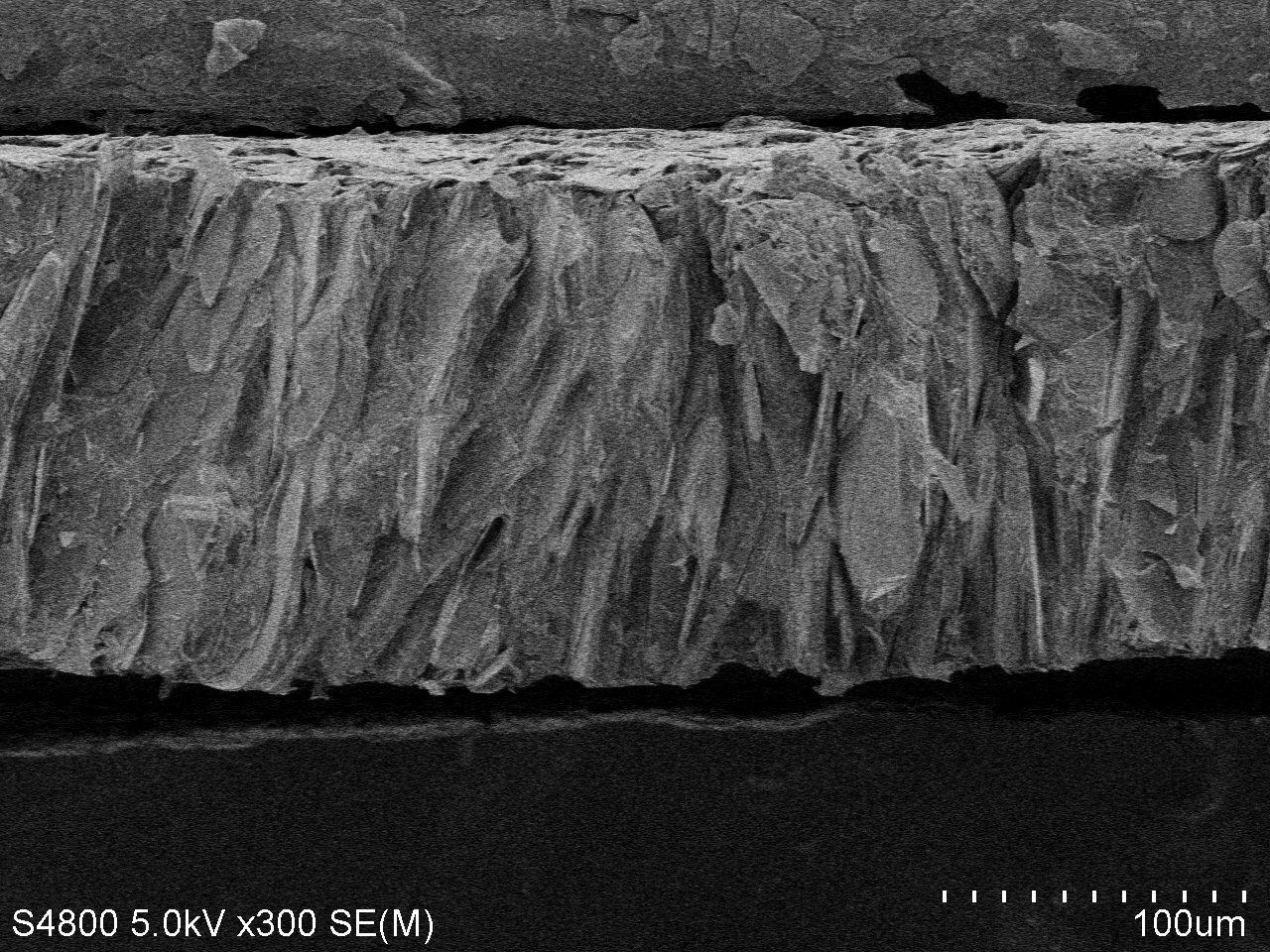

Vertical orientation control of thermal conductive filler

Electron micrograph of the cross-sectional structure of HEATEX™ with vertically oriented boron nitride

Handling

Silicone rubber as the material, it is hard to break even when bent, has a silky feel to it, and has excellent workability.

Rework is also possible.

Adhesive treatment of the sheet surface is available as an option.

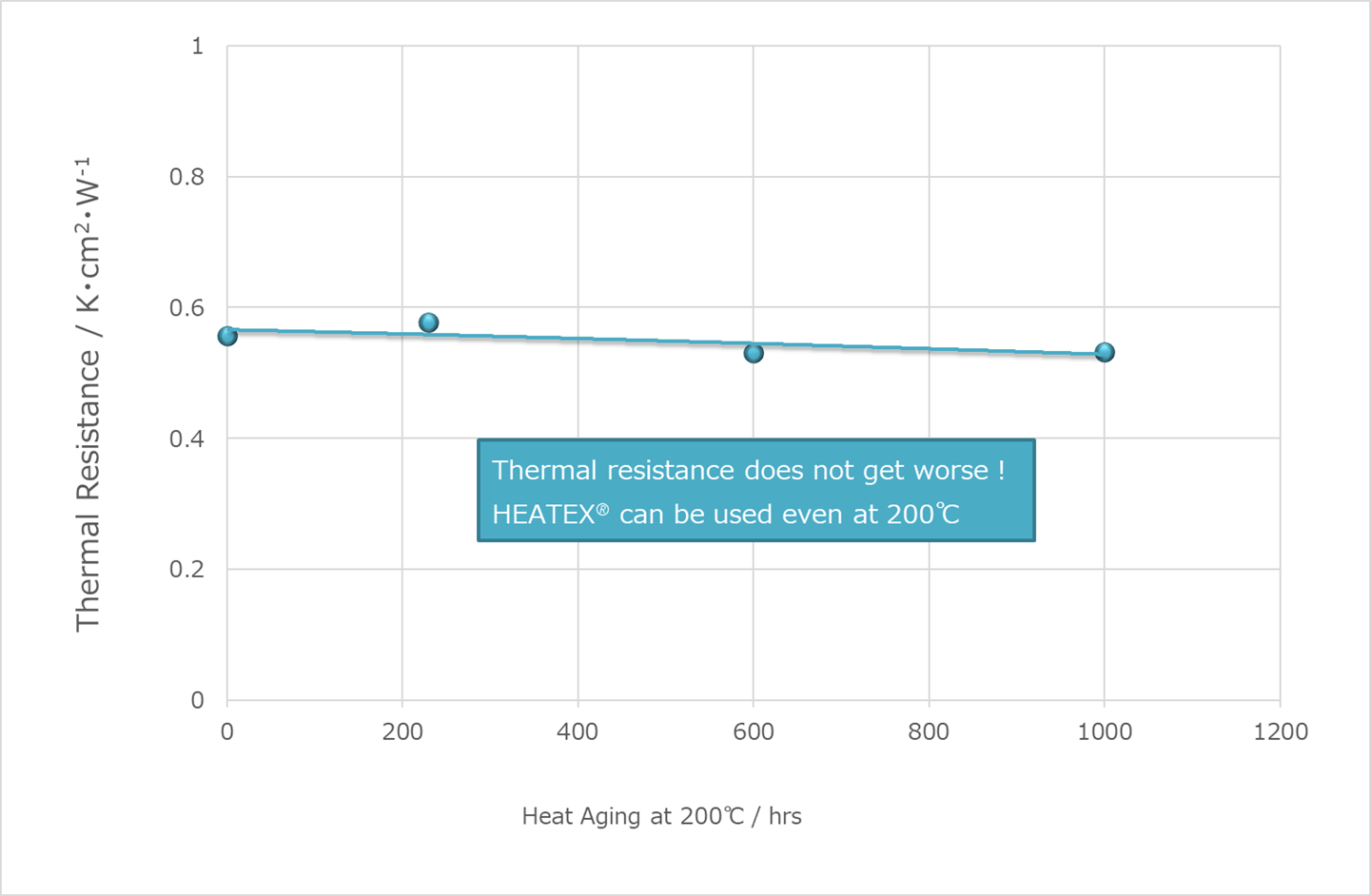

Thermal Stability

Maintains low thermal resistance in pressurized environments.

Even if it is used for a long time in an environment of 200°C, there is almost no change in physical properties.

In addition, the pump-out phenomenon caused by thermal paste is less likely to occur.

*Pump-out phenomenon

As materials expand and contract repeatedly due to the rise and fall of the temperature, the grease which was in contact with the materials will be pushed out, thus creating the pump-out phenomenon.

When the pump-out phenomenon occurs, the contact thermal resistance increases due to the formation of gaps, hence the initial efficiency cannot be attained.

Specifications

The values in the table are representative values. Specifications are subject to change without notice.

The above table data is also stored in Catalogs and Documents, and can be downloaded as a PDF file.

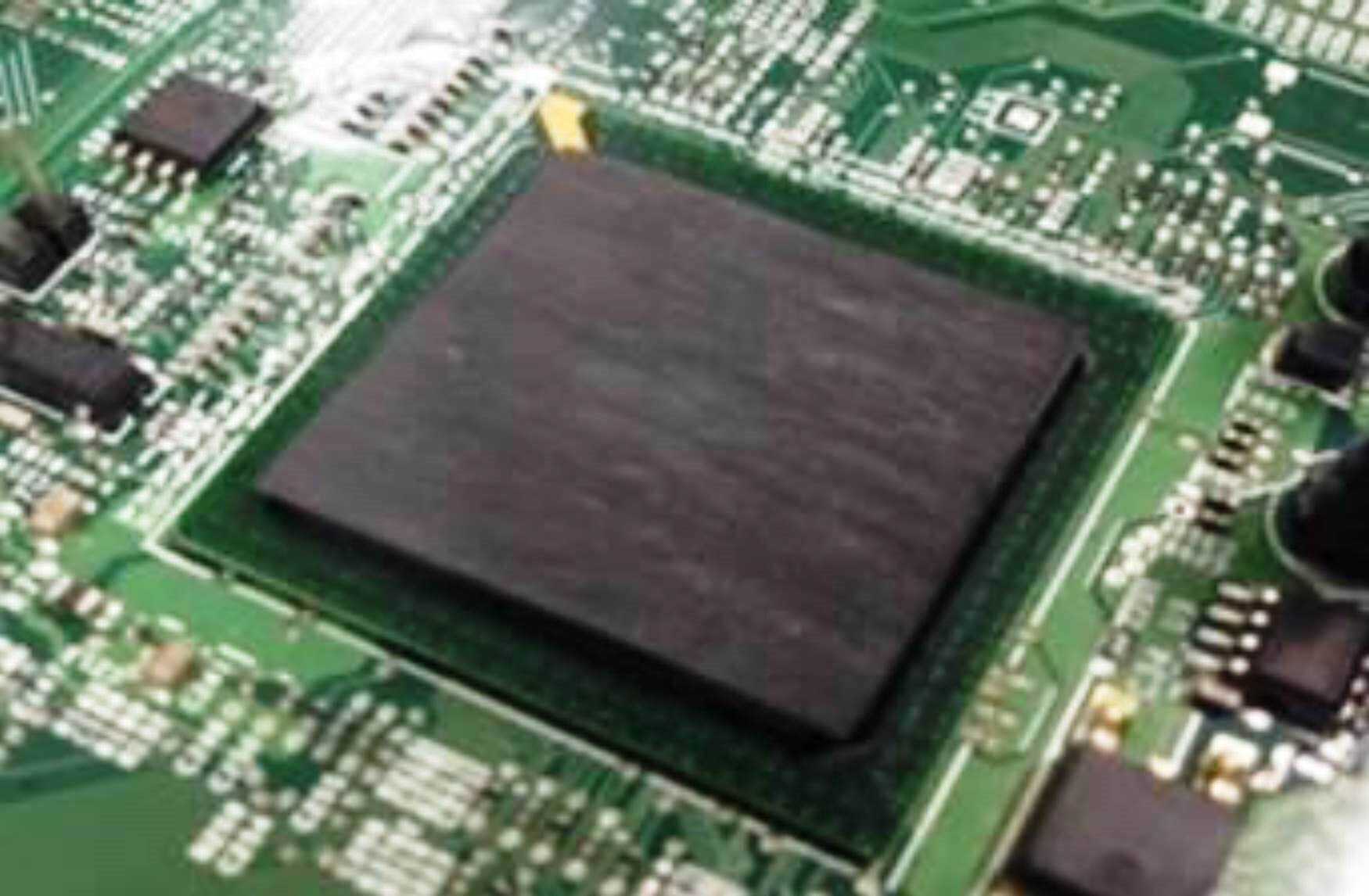

Applications

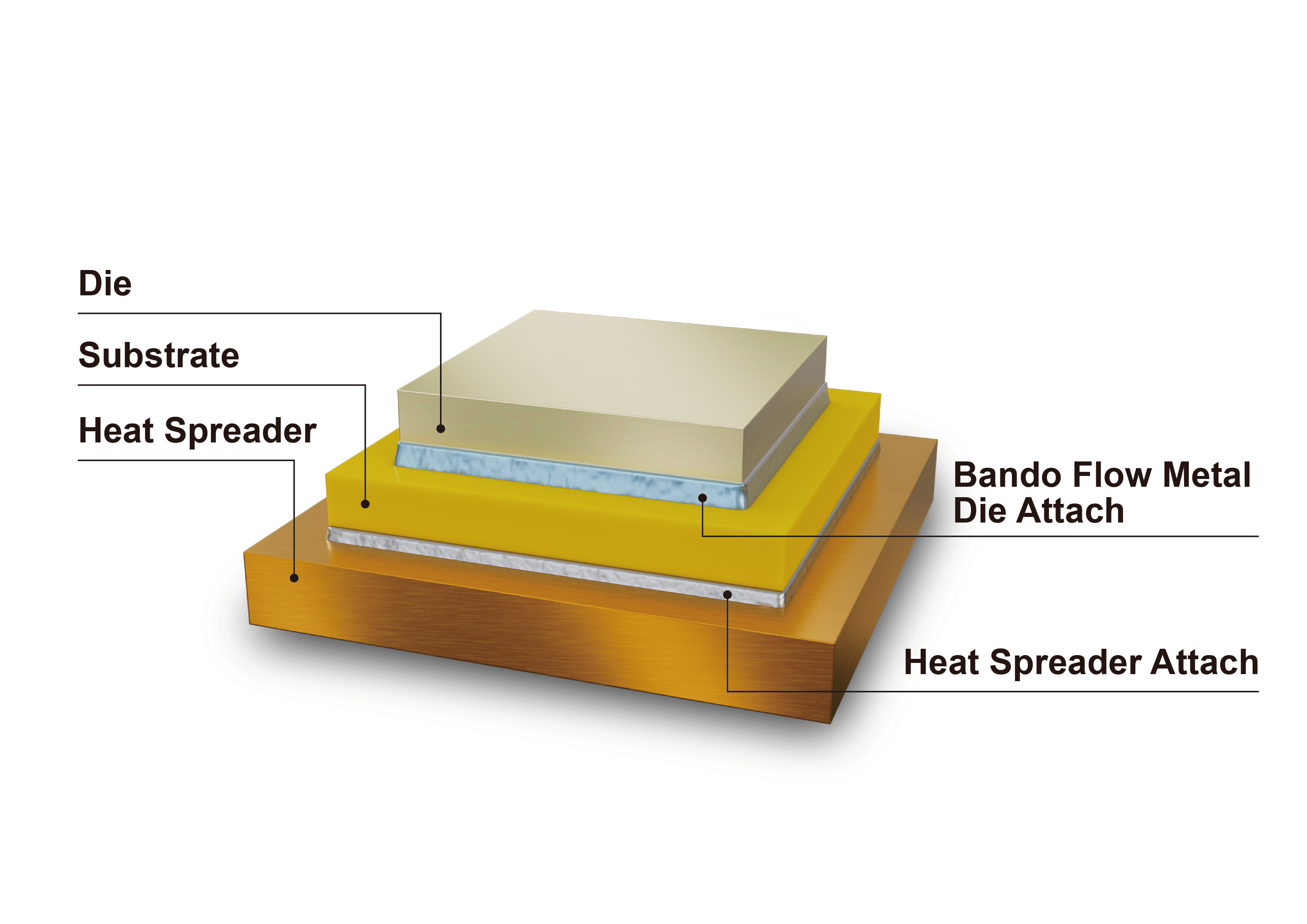

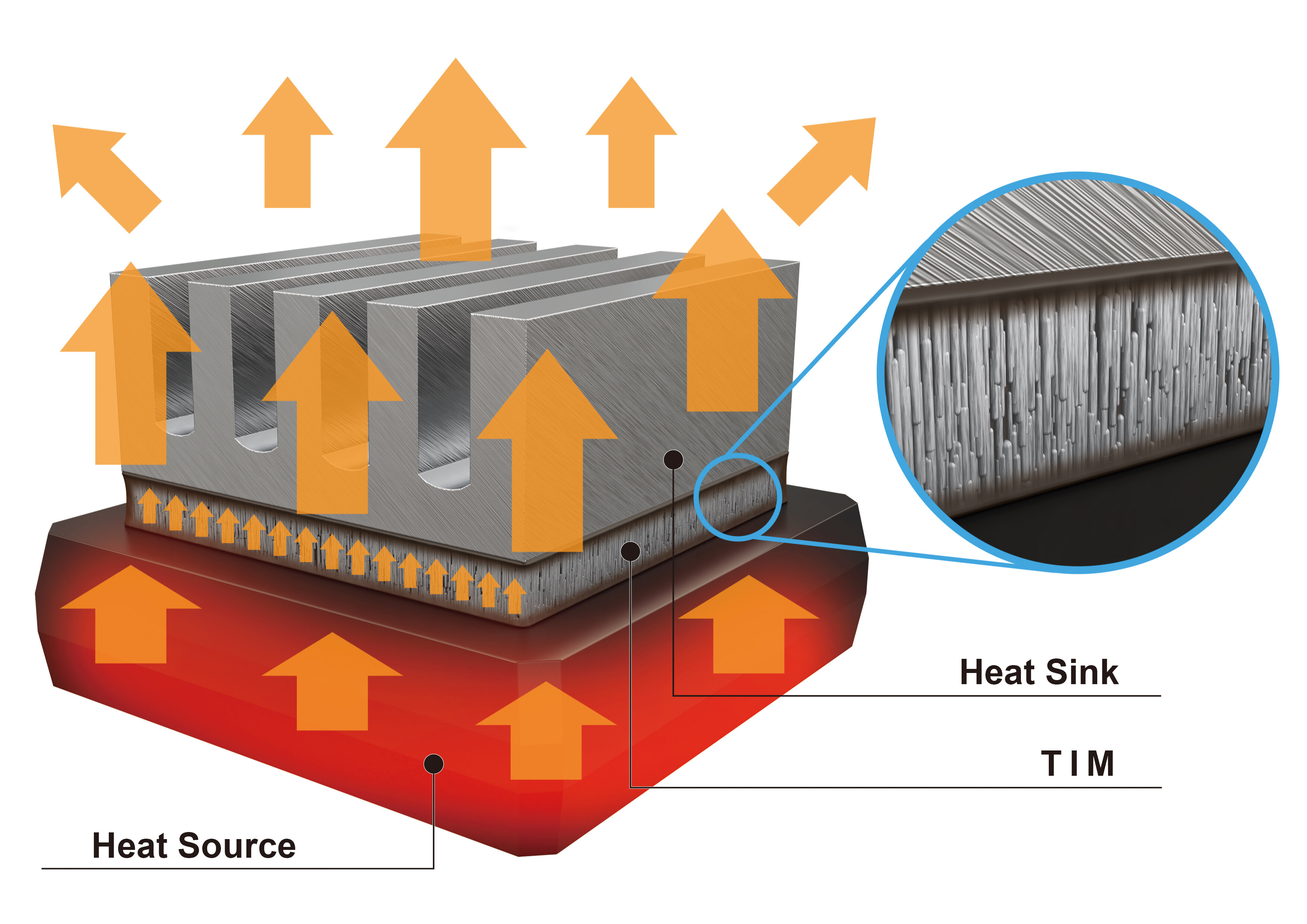

Image of HEATEX™ in use

Applications & Cases

Introducing our product applications and cases for various industries.