Why It’s Important to Select the Right Type of Timing Belt?

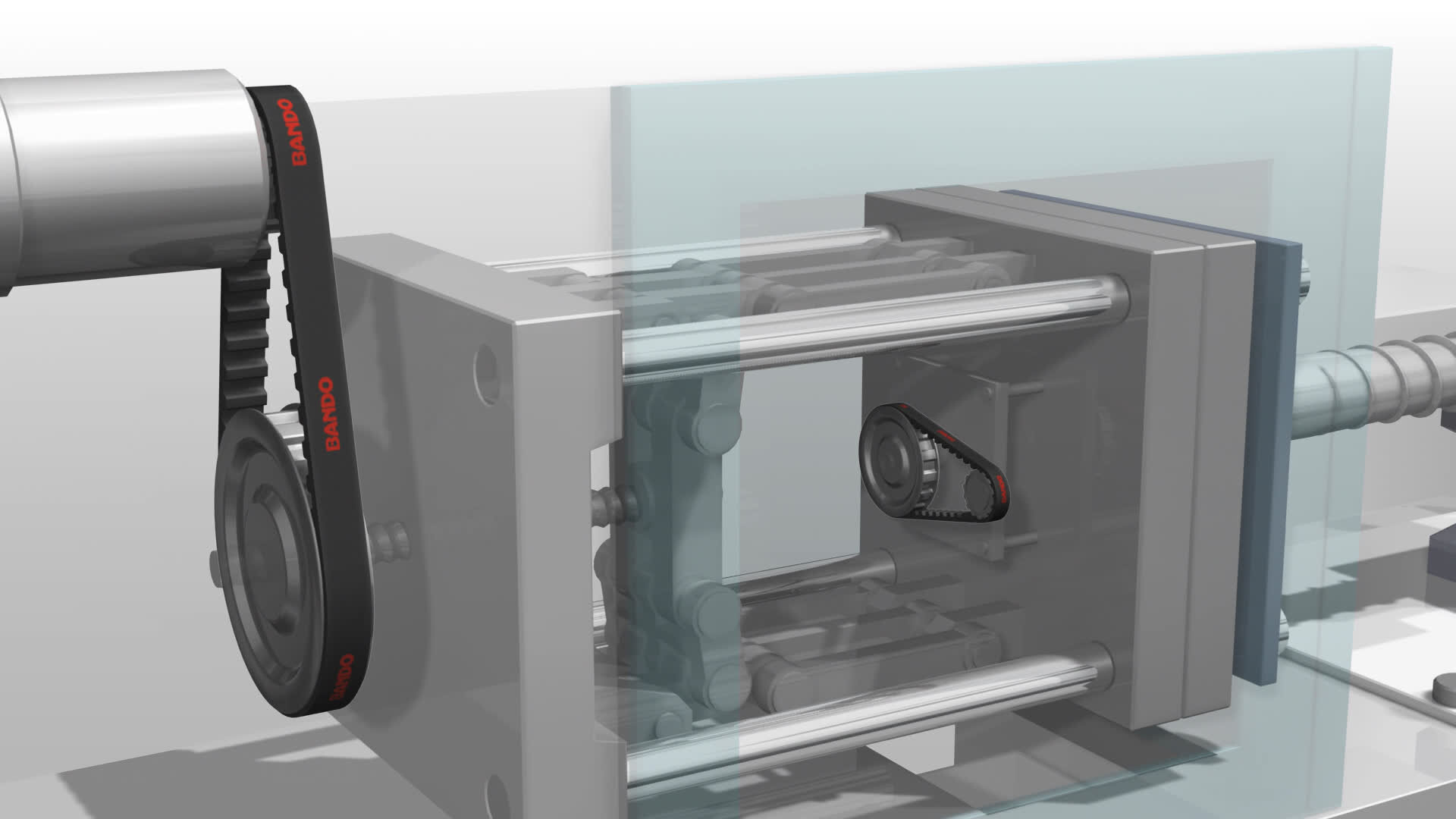

In industrial machinery, there are many different types of timing belts, each available in a wide variety of materials. If the selected timing belt does not match the machine’s operating conditions or environmental factors, not only will it fail to deliver its intended performance, but it may also lead to issues such as premature failure or unexpected downtime.

Therefore, selecting the appropriate timing belt based on the application and required performance specifications is critically important. In some cases, choosing the right belt type can even allow for a narrower belt width, enabling more compact and efficient machine designs. Understanding the key factors involved in timing belt selection can thus open up a wider range of design possibilities.

In this article, we will first explore the fundamental characteristics and performance of the two primary materials used in timing belts—rubber and polyurethane—and highlight their respective advantages. We will then provide guidance on how to select the most suitable timing belt for your specific needs.

Fundamental Characteristics and Performance of Rubber and Polyurethane Timing Belts

When selecting a timing belt, one of the most frequently asked questions is: “Should I choose a rubber or a polyurethane belt?” This is because timing belts are broadly classified into two main material types—rubber and polyurethane. Each material comes with its own set of advantages and disadvantages, making it essential to evaluate the options from multiple perspectives when making a selection.

Pros and Cons of Rubber and Polyurethane

■ Belt Dust Generation (Wear Rate)

This refers to the amount of material that wears off the belt during operation.

Polyurethane belts are generally more resistant to wear compared to rubber belts.

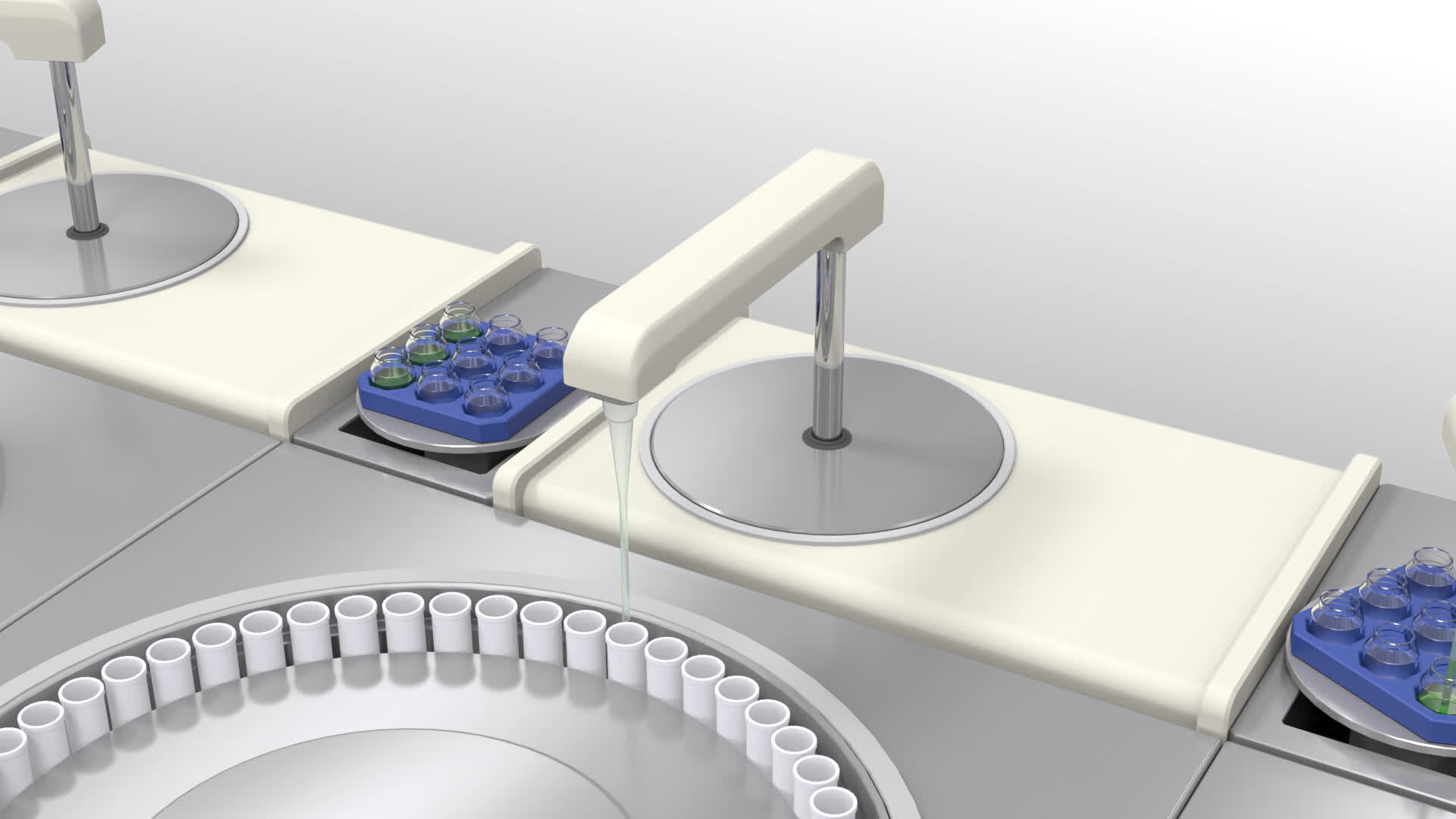

For environments where minimal belt dust is critical—such as cleanrooms—polyurethane belts are recommended.

■ Noise Reduction

Rubber belts typically have a fabric layer on the tooth surface, which helps reduce noise during operation.

As a result, rubber belts offer superior quietness compared to polyurethane belts.

■ Oil Resistance

Polyurethane belts excel in oil resistance, making them suitable for oily environments.

That said, certain rubber formulations—such as those using H-NBR—can also offer good oil resistance depending on their composition.

■ Heat Resistance

Rubber belts generally provide better heat resistance than polyurethane belts.

Depending on the specifications, some rubber belts can be used at temperatures up to 120°C.

As shown above, the choice of belt material depends largely on the specific performance characteristics required for the application. The most suitable material will vary depending on factors such as wear resistance, noise level, oil exposure, and operating temperature.

It’s important to note, however, that the comparison provided above focuses on the most common types of each material—chloroprene rubber and urethane rubber. In practice, variations within each material category can offer enhanced properties. For example, some rubber compounds are formulated for improved oil resistance, while certain types of polyurethane are designed to resist hydrolysis more effectively.

In the next section, we will take a closer look at the different types of rubber and polyurethane used in timing belts and explore their specific characteristics.

Types and Characteristics of Rubber

■ CR (Chloroprene Rubber)

Offers a wide usable temperature range and excellent overall rubber properties, making it highly versatile.

Also features self-extinguishing properties.

■ EPM/EPDM (Ethylene Propylene Rubber)

Exhibits excellent weather resistance, including high heat, cold, and ozone resistance.

However, it tends to wear more easily and has lower oil resistance compared to other rubber types.

■ NBR (Nitrile Butadiene Rubber)

Although increasingly being replaced by H-NBR, NBR remains notable for its superior oil resistance compared to CR.

Can be formulated to comply with FDA standards or produced in white variants for specific applications.

■ H-NBR (Hydrogenated Nitrile Butadiene Rubber)

Commonly used in automotive engine timing belts.

Provides excellent heat and oil resistance, though it is somewhat less resistant to cold and ozone compared to other rubbers.

Types and Characteristics of Polyurethane

Polyurethane refers to a group of polymer compounds characterized by urethane linkages. These materials are generally categorized based on their molecular structure into ester-based and ether-based types.

■ Ester-Based Polyurethane

Strong intermolecular interactions between ester groups result in high material strength.

However, ester groups are prone to hydrolysis, which makes polyester-based polyurethane more susceptible to degradation in humid or wet environments.

■ Ether-Based Polyurethane

While weaker in strength due to weaker intermolecular forces, it maintains flexibility even at low temperatures.

Ether groups are highly resistant to hydrolysis, making polyether-based polyurethane more durable in moisture-prone environments.

Our Polyurethane timing belts use ether-based polyurethane for superior durability and performance.

How to Use the Industrial Power Transmission Belt Product Search Tool

So far, we’ve explored the key characteristics of materials used in timing belts. However, selecting the right belt involves more than just understanding material properties. Factors such as machine load, belt speed, and operating environment must also be taken into account.

One highly recommended approach is to use an industrial power transmission belt product search tool. This web-based tool allows users to easily narrow down suitable belt types by entering required performance criteria and machine specifications. It simplifies the selection process and helps ensure that the chosen belt meets all necessary conditions for reliable, long-term performance.

Information Required for Using the Industrial Power Transmission Belt Product Search Tool

To use the Industrial Power Transmission Belt Product Search Tool, only the following three pieces of information are needed:

・Pitch diameter of the drive pulley

・Rotational speed

・Operating conditions (if applicable)

How to Use the Product Search Tool

1. Select the transmission method.

For timing belts, choose “Positive Engagement Drive”.

2. Enter the pitch diameter and rotational speed of the drive pulley.

The belt speed will be automatically calculated based on this information.

3. If you have specific requirements—such as oil resistance or flame retardancy—click on “Operating Conditions” and check the appropriate boxes.

4. Click “Search with These Conditions” to begin the search.

5. A list of product types that meet your criteria will be displayed.

Once you have narrowed down the belt type, it is essential to perform a more detailed calculation of the belt’s size and width. We encourage you to take full advantage of our “Belt Design and Selection Support Program” during this process.

Our Product Lineup

Lastly, we would like to introduce the lineup of toothed belts offered by Bando Chemical Industries. Our extensive product range is designed to meet a wide array of performance requirements. If you are uncertain about which toothed belt is best suited for your needs, please don’t hesitate to contact us. We are happy to offer support and consultation tailored to your application.